Woodworking

Marine fabrication

Wood

Foam

Non-ferrous metals

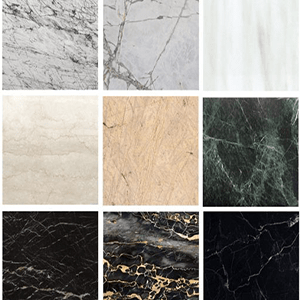

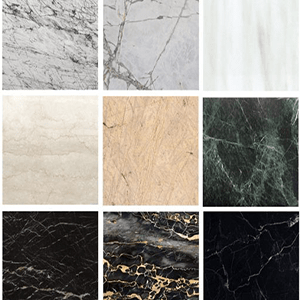

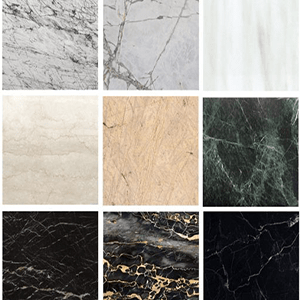

Composite materials

RECI,EFR,SPT

Water Cooling

Laser cutting is a technology that uses a laser to slice materials. While typically used for industrial manufacturing applications, it is beginning to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish

Generation of the laser beam involves stimulating a lasing material by electrical discharges or lamps within a closed container. As the lasing material is stimulated, the beam is reflected internally by means of a partial mirror, until it achieves sufficient energy to escape as a stream of monochromatic coherent light. Mirrors or fiber optics are typically used to direct the coherent light to a lens, which focuses the light at the work zone. The narrowest part of the focused beam is generally less than 0.0125 inches (0.32 mm) in diameter. Depending upon material thickness, kerf widths as small as 0.004 inches (0.10 mm) are possible. In order to be able to start cutting from somewhere other than the edge, a pierce is done before every cut. Piercing usually involves a high-power pulsed laser beam which slowly makes a hole in the material, taking around 5–15 seconds for 0.5-inch-thick (13 mm) stainless steel

Application Area